|

|

Joint Protection of Pre-Insulated Pipes

| JOINT PROTECTION WITH TIAL-TUM ONE-PIECE CASING |

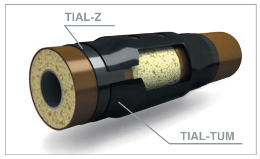

TIAL-TUM one-piece heat-shrinkable casing is specifically designed for complete joint protection of pre-insulated pipelines for underground laying.One-piece structure of the casing allows to execute waterproofing that meets the highest requirements, though the installation is carried out in a simple way which does not require high qualification of field crew. This one-piece structure eliminates the need of additional end seals.

TIAL-TUM is manufactured of HDPE via extrusion process followed by specifically oriented stretching to obtain shrinkage. The casing is cross-linked to prevent buckling and to impart excellent mechanical strength due to high impact, indentation and abrasive resistance. |

|

| RECOMMENDED CASING LENGTH |

|

The inner non-shrinkable HDPE layer is built into the middle section of TIAL-TUM system to prevent deformation. This extremely solid layer structure additionally reinforces the construction to provide full resistance to soil stress.

TIAL-TUM is used together with TIAL-Z unique hotmelt adhesive. TIAL-Z serves for complete and long-term sealing of casing ends thanks to its high peel and lap shear strength. TIAL-Z is supplied as part of TIAL-TUM set preliminary cut for specific diameter. As an option TIAL-Z can be supplied in 30 m rolls.

TIAL-TUM operates at environmental temperatures from - 60 to + 60 °С.Lifetime of TIAL-TUM casing is minimum 45 years. |

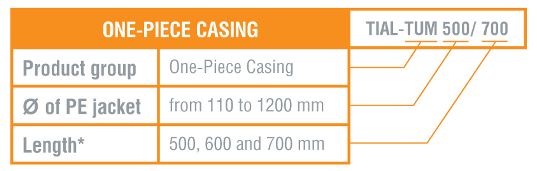

| ORDERING INFORMATION: |

|

*Standard length can be changed upon customer request.

BENEFITS

- complete sealing

- comprehensive weld joint area protection againstunderground, flood and other waste waters

- no deformation due to hardness of middle section layer

- no additional end seals

- excellent resistance to soil stresses

- complete set of component parts

- over 30% shrinkage

|

JOINT PROTECTION WITH TIAL-M SLEEVES

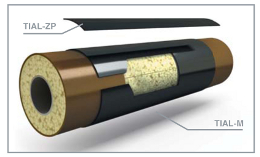

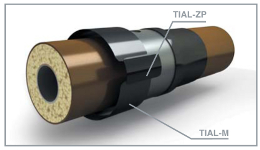

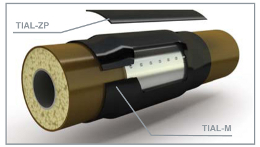

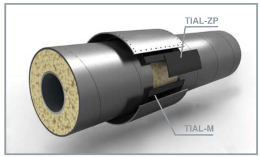

ТIAL-М heat-shrinkable wrap-around sleeve is used for sealing of weld joint areas of pre-insulated pipelines.

The sleeve has two-layer structure (PE backing and hotmelt adhesive).

The backing provides with high indentation resistance, impact strength and extremely low moisture absorption. The backing is cross-linked to prevent tape from buckling and to impart specific mechanical strength and resistance to UV-radiation.

Adhesive layer of the sleeve possesses high peel and shear strength.

TIAL-M sleeve is fixed on the pipe surface with the help of TIAL-ZP fiberglass reinforced closure patch.

The closure patch is delivered in set together with the sleeve.

To ensure mobility of the works and to simplify logistic schemes TIAL-M sleeves can be delivered in 30 running meter rolls. The rolls are cut to the required length by installation crew on site.

Lifetime of TIAL-M sleeve is minimum 45 years.

|

| SEALING OF PRE-INSULATED JOINTS WITH TIAL-M SLEEVE |

|

BENEFITS

- complete sealing

- comprehensive weld joint area protection against underground, flood and other waste waters

- high peel and shear strength

- excellent resistance to soil shear forces

|

| UNDERGROUND PIPELINES PRE-INSULATED WITH POLYURETHANE FOAM (PUF) SHELLS |

Nowadays heat-shrinkable all-in-one casings for sealing of pre-insulated pipeline joints are preferable. However when the carrier pipe sections has been already welded the tubular casing can not be installed. In this case TIAL-M wraparound sleeve is an indispensable product for coating of joints of pre-insulated pipes.

Taking into account economical aspect, application of the sleeve is more preferable due to lower cost of the sleeve in comparison with one-piece casing. Additionally, time for installation process is greatly minimized. These both factors significantly reduce the cost of pipeline construction. |

|

| When there are no strict requirements to hardness of the coating, TIAL-M sleeve is the ideal decision. |

| UNDERGROUND PIPELINES PRE-INSULATED WITH PE OR STEEL PROTECTIVE JACKETS |

|

|

| Another means to replace all-in-one casing for sealing of joint areas of buried pre-insulated pipelines is PE or zinc-galvanized steel jacket application. The jackets impart additional hardness to the whole coating system for a joint. In this case TIAL-M sleeve is the ideal decision for waterproofing of the whole system protecting joint area. |

| ABOVEGROUND PIPELINES PRE-INSULATED WITH GALVANIZED STEEL PROTECTIVE JACKETS |

Qualitative sealing of joint areas is always an important goal during exposed pre-insulated pipeline construction. TIAL-M sleeve is optimal decision when the main coating of the pipeline is zinc-galvanized steel.

In place where PU foam and galvanized steel contact each other there is often a problem to resist different speed of PUF and steel cooling down.TIAL-M sleeve eliminates this specific problem due to its high durability. |

|

|

|

|

|